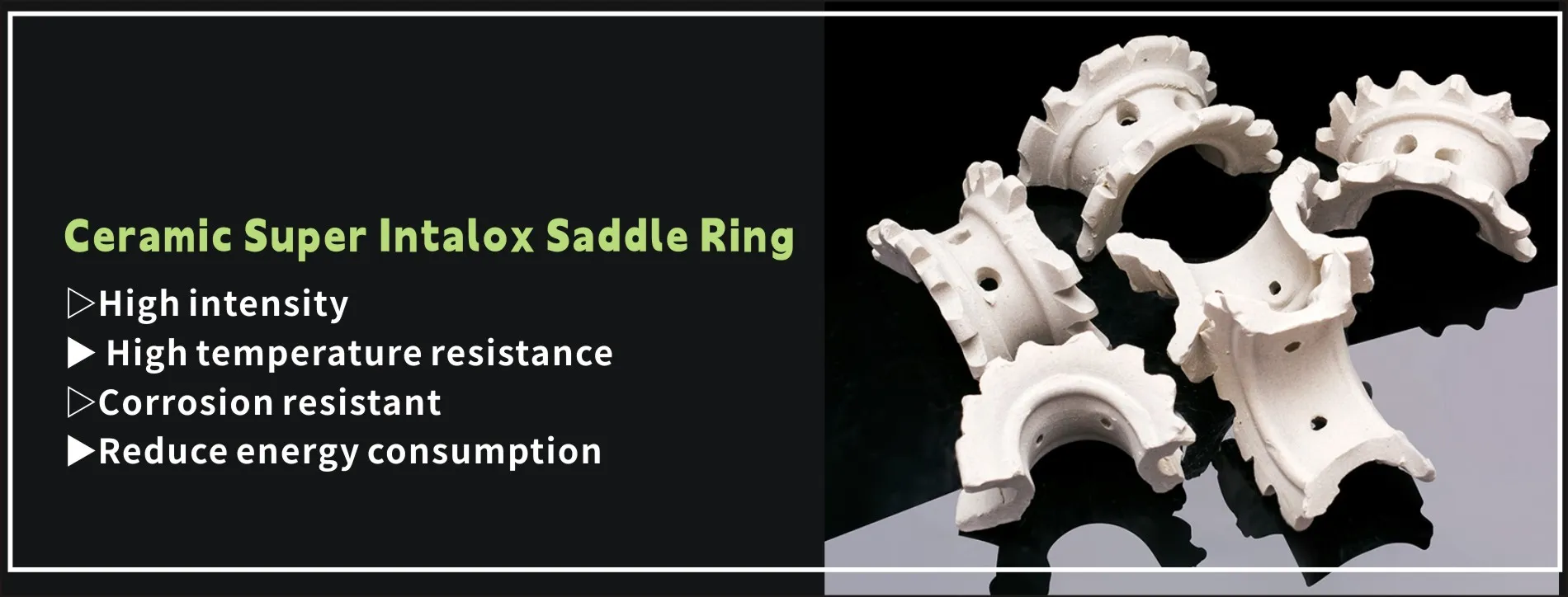

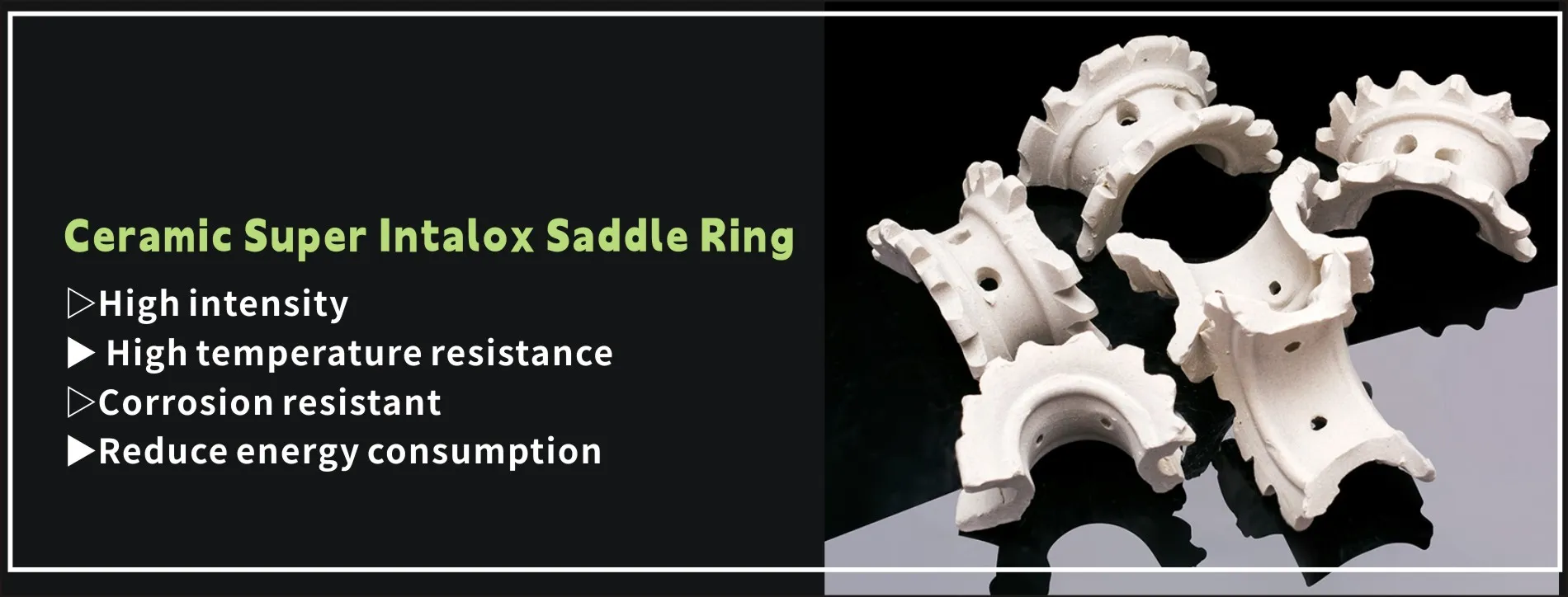

Ceramic Super Intalox Saddle Ring

Products introduction:

Ceramic Super Intalox Saddle is improved from the ceramic Intalox saddle,Ceramic super intalox saddle changes the both arched surface with gears this construction can improve the surface area and voidage,

Ceramic Super Intalox Saddle is improved from the ceramic Intalox saddle,Ceramic super intalox saddle changes the both arched surface with gears this construction can improve the surface area and voidage,

Product Details

Ceramic super intalox saddle makes porosity distributed even and improves the distribution of the fluid, greater capacity and lower pressure drop than ceramic rasching ring.

Ceramic Super Intalox Saddle with excellent acid resistance and heat resistance. They can resist to corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions.Consequently their application ranges are very wide.Ceramic Intalox Saddle can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc. Ceramic Super Intalox Saddles are used in two main fields but have different properties depending on the application. One field is the chemical and petrochemical industries and another is in environmental areas such as RTO equipment.

Technical data

|

SiO2 + Al2O3 |

>92% |

CaO |

<1.0% |

|

SiO2 |

>76% |

MgO |

<0.5% |

|

Al2O3 |

>17% |

K2O+Na2O |

<3.5% |

|

Fe2O3 |

<1.0% |

Other |

<1% |

Physical & Chemical properties

|

Water absorption |

<0.5% |

Moh’s hardness |

>6.5 scale |

|

Porosity (%) |

<1 |

Acid resistance |

>99.6% |

|

Specific gravity |

2.3-2.40 g/cm3 |

Alkali resistance |

>85% |

|

Max Operation temp |

950~1100℃ |

|

|

Dimension and Other Physical Properties

|

Size |

Thickness (mm) |

Specific Surface (m2/m3) |

Void Volume (%) |

Bulk Numbers (Pcs/m3) |

Package Density (kg/m3) |

|

25mm |

3-3.5 |

160 |

78 |

53000 |

650 |

|

38mm |

4-5 |

102 |

80 |

16000 |

600 |

|

50mm |

5-6 |

88 |

80 |

7300 |

580 |

|

76mm |

8.5-9.5 |

58 |

82 |

1800 |

550 |

Other size also can be provided by custom made!

Ceramic super intalox saddle makes porosity distributed even and improves the distribution of the fluid, greater capacity and lower pressure drop than ceramic rasching ring.

Ceramic Super Intalox Saddle with excellent acid resistance and heat resistance. They can resist to corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions.Consequently their application ranges are very wide.Ceramic Intalox Saddle can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc. Ceramic Super Intalox Saddles are used in two main fields but have different properties depending on the application. One field is the chemical and petrochemical industries and another is in environmental areas such as RTO equipment.

Technical data

|

SiO2 + Al2O3 |

>92% |

CaO |

<1.0% |

|

SiO2 |

>76% |

MgO |

<0.5% |

|

Al2O3 |

>17% |

K2O+Na2O |

<3.5% |

|

Fe2O3 |

<1.0% |

Other |

<1% |

Physical & Chemical properties

|

Water absorption |

<0.5% |

Moh’s hardness |

>6.5 scale |

|

Porosity (%) |

<1 |

Acid resistance |

>99.6% |

|

Specific gravity |

2.3-2.40 g/cm3 |

Alkali resistance |

>85% |

|

Max Operation temp |

950~1100℃ |

|

|

Dimension and Other Physical Properties

|

Size |

Thickness (mm) |

Specific Surface (m2/m3) |

Void Volume (%) |

Bulk Numbers (Pcs/m3) |

Package Density (kg/m3) |

|

25mm |

3-3.5 |

160 |

78 |

53000 |

650 |

|

38mm |

4-5 |

102 |

80 |

16000 |

600 |

|

50mm |

5-6 |

88 |

80 |

7300 |

580 |

|

76mm |

8.5-9.5 |

58 |

82 |

1800 |

550 |

Other size also can be provided by custom made!

Packaging & Shipping

|

Package Type |

Container Load Capacity |

||

|

20 GP |

40 GP |

40 HQ |

|

|

Ton bag |

20-24 m3 |

40 m3 |

48 m3 |

|

Plastic bag |

25 m3 |

54 m3 |

65 m3 |

|

Paper box |

20 m3 |

40 m3 |

40 m3 |

|

Delivery time |

Within 7 working days |

10 working days |

12 working days |

|

Comments: |

Customized making is allowed. |

||

Packaging & Shipping

|

Package Type |

Container Load Capacity |

||

|

20 GP |

40 GP |

40 HQ |

|

|

Ton bag |

20-24 m3 |

40 m3 |

48 m3 |

|

Plastic bag |

25 m3 |

54 m3 |

65 m3 |

|

Paper box |

20 m3 |

40 m3 |

40 m3 |

|

Delivery time |

Within 7 working days |

10 working days |

12 working days |

|

Comments: |

Customized making is allowed. |

||

Leave us your information and one of our experts will assist you